Dedicated to providing the best possible service, our team of vacuum technicians are trained to not only service Atlas Copco Vacuum products – but all major vacuum pump brands.

Now offering the next-generation vacuum controller with complete connectivity and enhanced control.

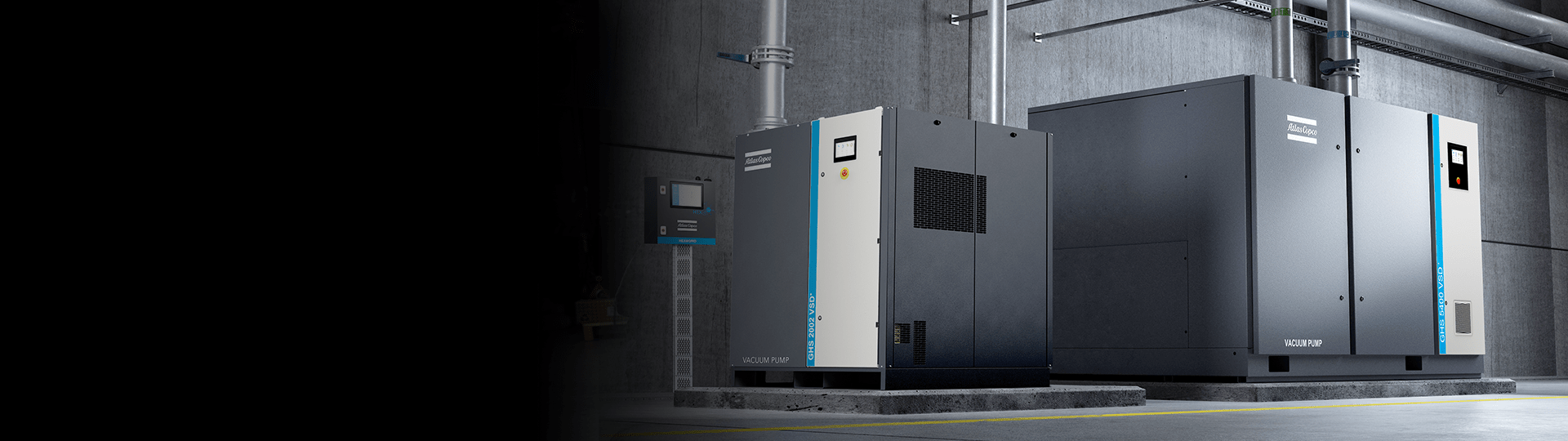

Atlas Copco’s oil-sealed rotary screw vacuum pumps combines robust technology with Atlas Copco’s advanced vacuum know-how.

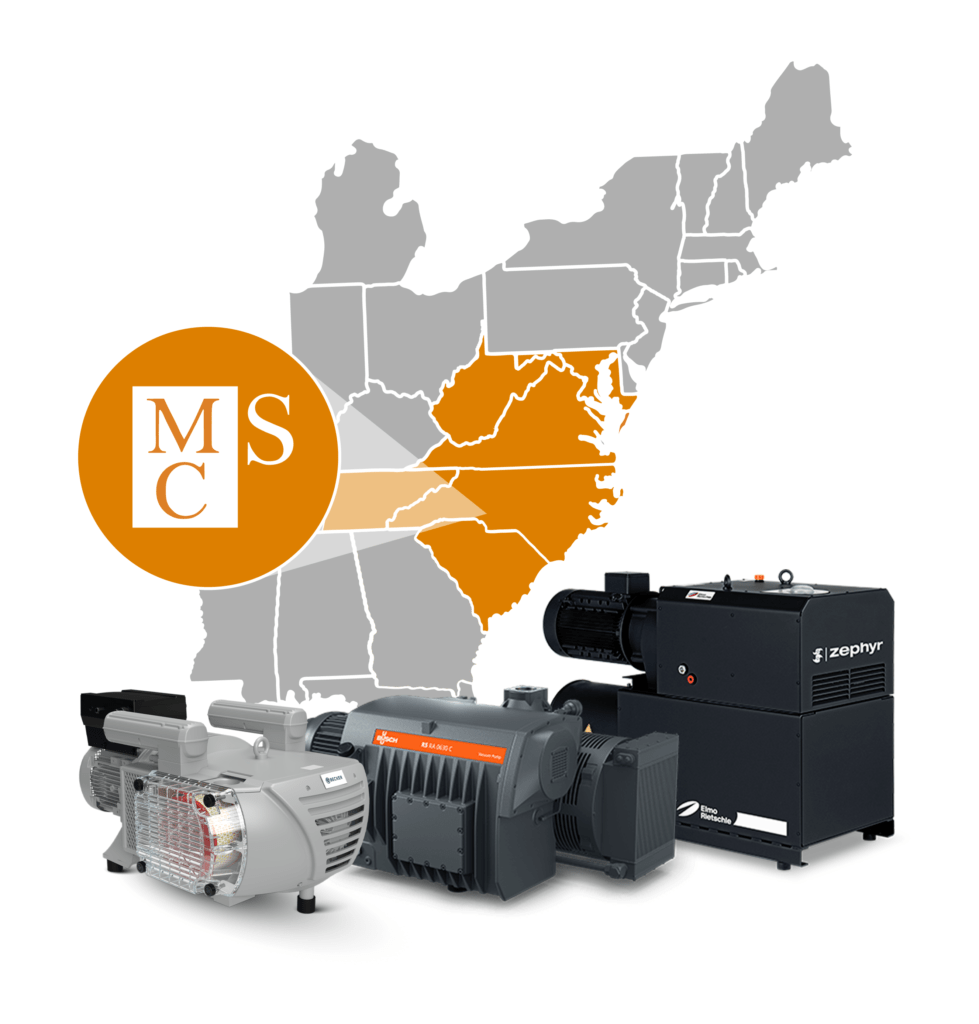

Who is M.C. Schroeder EquipmentTM

Since 1970, M.C. Schroeder Equipment has established itself as the region’s leading supplier of industrial vacuum solutions and service for the process industries. With our office located in Denver, North Carolina, we are well positioned to meet our customers’ needs promptly throughout North Carolina, South Carolina, Virginia, Maryland, Georgia, and Eastern Tennessee. A part of the Atlas Copco Group and a distributor of their vacuum solutions, we offer a full line of vacuum pumps, systems, and accessories to meet the growing needs of today’s industrial market.

Dedicated to providing the best possible service to your business, our team of vacuum experts are trained to not only service Atlas Copco Vacuum products – but all major vacuum pump brands. Our main goal is to get repairs done quickly to reduce the potential lost productivity and revenue for your business.

We service all major vacuum pump brands including:

- Atlas Copco

- Busch

- SIHI

- Becker

- Nash

- Dekker

- Elmo Rietschle

- Leybold

- Edwards

- Quincy

- Tuthill

- Kaeser

M.C. Schroeder EquipmentTM Mission Statement

Our employees look to create a customer relationship that can connect the customer’s needs with the process solutions from our vendors.

Our Products

As a part of the Atlas Copco Group and a distributor of their vacuum solutions, we offer a full line of vacuum pumps, systems, parts and accessories to meet the growing needs of today’s industrial market.

Service & Repair

M.C. Schroeder EquipmentTM offers after-sales support for vacuum pumps including maintenance, service and a substantial line of spare parts. Our well-connected service centers can deliver the high quality vacuum service for your equipment. To keep your vacuum pump and system efficient and in optimum working condition throughout its lifetime, service support is available in your location; tailored to your specific needs and delivered by our trained experts.

Our Team

Since 1970, our team at M.C. Schroeder Equipment has established itself as the region’s leading supplier of industrial vacuum solutions and service for the process industries for all of North Carolina, South Carolina, Virginia, Maryland, Georgia, and Eastern Tennessee.